When designing or troubleshooting hydraulic systems, one crucial component engineers often come across is the flow divider. For seasoned professionals and newcomers alike, understanding what flow dividers are, how they work, and where they are used is essential to optimizing performance and efficiency in hydraulic systems.

This guide will provide a comprehensive overview of flow dividers, their different types, applications, and how they interact with other hydraulic components like industrial gear pumps. You’ll also discover valuable insights into selecting the right flow divider for your system needs.

What Is a Flow Divider?

A flow divider is a hydraulic component designed to split, manage, or allocate the flow of hydraulic fluid within a system. Its main purpose is to ensure that the fluid flow is consistently distributed between two or more actuators or branches of a system. The result is synchronized motion or balanced force in applications requiring precise control.

By splitting the flow, a flow divider helps prevent inefficiencies like uneven load distribution or excessive wear on hydraulic components.

Why Are Flow Dividers Used in Hydraulic Systems?

Flow dividers address several common challenges in hydraulic systems:

- Synchronized Motion: Systems with multiple cylinders or motors require synchronized operation. A flow divider ensures each actuator receives the right amount of hydraulic fluid to move uniformly.

- Energy Efficiency: By directing fluid where it’s needed most, a flow divider minimizes power loss and optimizes system efficiency.

- Reduced Component Wear: Balanced fluid flow reduces stress on system components such as industrial gear pumps and actuators, extending their operational life.

How Do Flow Dividers Work?

Flow dividers typically function by splitting the hydraulic fluid flow from a supply pump into two or more paths. These paths can deliver equal or varied amounts of fluid depending on the design. The mechanism behind a flow divider depends on its type, which we’ll explore below.

Some common terms associated with flow dividers include:

- Input Flow: The main stream of hydraulic fluid entering the divider.

- Output Flow: The streams of hydraulic fluid that leave the divider and travel to different actuators.

- Metering: The process of accurately controlling fluid flow to specific outlets.

To complement a flow divider’s capability, components like high-pressure gear pumps or industrial gear pumps often supply the hydraulic fluid with the necessary power and pressure. Compatibility between these components ensures smooth and efficient operation.

Types of Flow Dividers

There are multiple types of flow dividers, each suited to specific hydraulic applications. Here’s a breakdown of the most common ones:

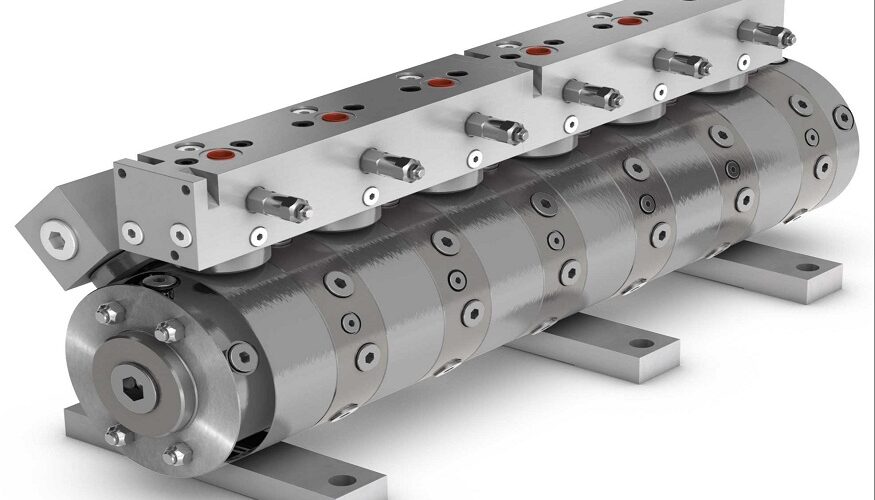

Rotary Gear Flow Dividers

Rotary gear flow dividers incorporate gears that rotate in precise synchronization with the input flow.

- Ideal for use with high-pressure gear pumps.

- Suitable for systems requiring consistent and proportional flow splitting.

Spool-Type Flow Dividers

Spool-type flow dividers employ sliding spools to divide and control fluid. These are often used in settings where variable flow rates are necessary. The design allows for:

- Excellent accuracy in metering flow.

- Adjustment of flow proportions for customizable system performance.

Pressure-Compensated Flow Dividers

This type of flow divider uses pressure valves to maintain consistent output regardless of pressure imbalances. Features include:

- Excellent for balancing hydraulic loads.

- Ideal for systems where pressure fluctuation is frequent.

Motorized Flow Dividers

Motorized flow dividers leverage hydraulic motors to split flow while maintaining efficiency. Benefits include:

- High torque capability.

- Application in heavy-duty hydraulic systems.

Applications of Flow Dividers

Flow dividers find application in various industrial and commercial sectors, including:

Automotive Manufacturing

Flow dividers ensure synchronized movement of robotic arms performing tasks like welding, assembly, or painting in automotive production lines.

Agriculture and Forestry Equipment

Hydraulic systems in tractors, harvesters, and logging equipment utilize flow dividers for even operation of lifting arms, blades, or conveyor systems.

Construction and Earth-Moving Machines

Bulldozers, excavators, and cranes use flow dividers to coordinate the movement of hydraulic cylinders, ensuring precision in load handling.

Food Processing

Flow dividers are also used in optimizing the movement of automation tools, including chocolate transfer pumps, where precise fluid handling is crucial.

Renewable Energy Systems

Hydraulic systems in wind turbines and hydropower plants often utilize flow dividers for fluid distribution, ensuring smooth performance in energy generation setups.

Choosing the Right Flow Divider for Your System

Selecting the correct flow divider involves several key factors:

- Flow Capacity: Determine the maximum flow rate your hydraulic system will handle.

- Operating Pressure: Ensure compatibility with high-pressure systems, especially those powered by high-pressure gear pumps.

- System Requirements: Identify whether your system requires equal flow splitting or variable proportions for specific tasks.

- Material and Build: Choose durable materials, especially in high-wear industries like construction and manufacturing.

- Compatibility: Verify compatibility between the flow divider and other core components, such as industrial gear pumps and actuators.

For expert-level hydraulic system performance, carefully matching a flow divider to your operational needs is crucial.

Essential Tips for Hydraulic Engineers

Adding flow dividers to your system requires thoughtful planning. Here are some tips to help you optimize system performance:

- Regularly inspect and maintain flow dividers to ensure they function within their operational specifications.

- Use high-pressure gear pumps to enhance the overall efficiency and reliability of fluid distribution in your hydraulic system.

- For complex systems, consider consulting specialists to design and optimize hydraulic layouts featuring flow dividers.

Build Efficiency into Your Hydraulic Systems with Flow Dividers

Flow dividers are indispensable tools within hydraulic systems, offering unmatched control, efficiency, and precision. From ensuring synchronized motion to balancing loads in cutting-edge machinery, their applications span industries and contribute to smooth system operation.

By understanding the types of flow dividers available and their respective use cases, hydraulic engineers can make informed decisions to optimize their setups. Whether you’re dealing with chocolate transfer pumps or high-pressure industrial pumps, integrating flow dividers brings you a step closer to operational excellence.